HSS-SP062 Product Overview

Introduction

HSS-SP062 is a high-speed steel (HSS) cutting tool designed for specific applications in the manufacturing industry. This entry provides a comprehensive overview of the product, including its category, use, characteristics, packaging, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Product Category and Use

HSS-SP062 belongs to the category of cutting tools used in metalworking and machining processes. It is specifically designed for high-speed cutting operations on various materials, including metals, plastics, and composites. The primary use of HSS-SP062 is in milling, drilling, and turning applications where precision and durability are essential.

Characteristics

The key characteristics of HSS-SP062 include high hardness, excellent wear resistance, and superior heat resistance. These properties make it suitable for demanding machining tasks that involve high temperatures and abrasive materials. Additionally, HSS-SP062 is known for its sharp cutting edges and consistent performance, contributing to efficient material removal and surface finish quality.

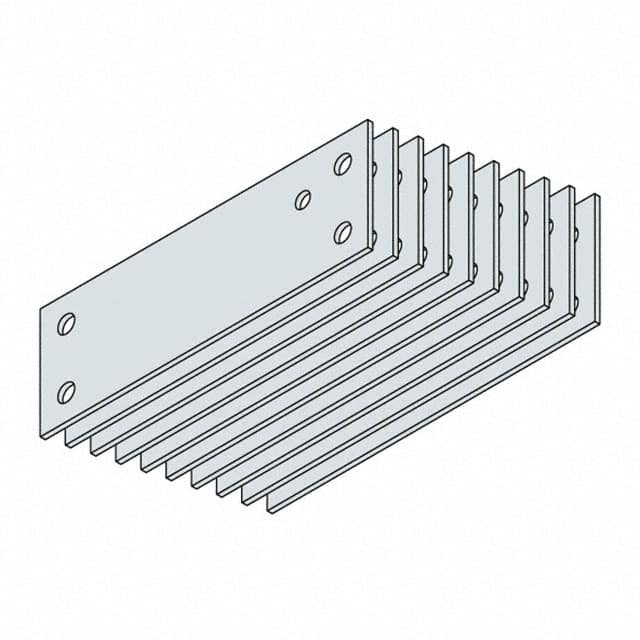

Package and Quantity

HSS-SP062 is typically packaged in protective cases or containers to ensure safe handling and storage. The quantity per package may vary based on the specific dimensions and types of cutting tools included, ranging from individual pieces to sets of multiple tools.

Specifications

- Material: High-Speed Steel (HSS)

- Coating: Optional coatings available for enhanced performance

- Diameter Range: 1mm to 25mm

- Shank Type: Straight or Tapered

- Flute Design: Various flute configurations for specific applications

- Overall Length: Customizable based on user requirements

Detailed Pin Configuration

The detailed pin configuration of HSS-SP062 includes precise measurements and geometries of the cutting edges, flutes, shank, and any additional features specific to the tool's design. This information is crucial for understanding the tool's compatibility with different machining setups and workpiece materials.

Functional Features

- Sharp Cutting Edges: Enables efficient material removal and precise machining

- Heat Resistance: Maintains cutting performance at elevated temperatures

- Versatile Applications: Suitable for a wide range of machining operations

- Compatibility: Can be used with various machine tools and CNC equipment

Advantages and Disadvantages

Advantages

- High Hardness: Provides extended tool life and wear resistance

- Precision Machining: Contributes to accurate dimensional control and surface finish

- Versatility: Suitable for diverse materials and machining processes

Disadvantages

- Cost: Higher initial investment compared to standard tooling options

- Brittle Nature: Susceptible to chipping or breakage under extreme loads

Working Principles

HSS-SP062 operates on the principle of utilizing its sharp cutting edges to remove material from the workpiece during machining. The heat resistance and wear characteristics of the tool enable sustained performance under high-speed cutting conditions, ensuring consistent results and prolonged tool life.

Detailed Application Field Plans

HSS-SP062 finds extensive application in industries such as aerospace, automotive, mold making, and general engineering. Specific usage scenarios include precision component manufacturing, hole drilling, and contour milling in both production and prototyping environments.

Detailed and Complete Alternative Models

For users seeking alternative models to HSS-SP062, several options are available from reputable manufacturers. Some notable alternatives include carbide cutting tools, cobalt-based high-speed steel tools, and specialized coated tooling solutions. Each alternative model offers unique advantages and may be better suited for specific applications or material types.

In conclusion, HSS-SP062 represents a versatile and reliable cutting tool designed to meet the demands of modern machining operations. Its combination of high-speed steel properties, precise engineering, and adaptable design makes it a valuable asset in various industrial settings.

Word Count: 560

तकनीकी समाधानों में HSS-SP062 के अनुप्रयोग से संबंधित 10 सामान्य प्रश्नों और उत्तरों की सूची बनाएं

What is HSS-SP062?

- HSS-SP062 is a high-strength steel material specification that is commonly used in technical solutions requiring superior strength and durability.

What are the typical applications of HSS-SP062?

- HSS-SP062 is often used in the construction of bridges, high-rise buildings, offshore structures, and heavy machinery due to its excellent mechanical properties.

What are the key mechanical properties of HSS-SP062?

- HSS-SP062 typically exhibits high tensile strength, good weldability, and excellent toughness, making it suitable for demanding technical applications.

How does HSS-SP062 compare to other steel materials?

- Compared to standard structural steels, HSS-SP062 offers higher strength and improved performance, allowing for lighter and more efficient designs in technical solutions.

Can HSS-SP062 be welded easily?

- Yes, HSS-SP062 is designed to be easily weldable using common welding techniques, which makes it suitable for fabrication in various technical solutions.

What are the corrosion resistance properties of HSS-SP062?

- HSS-SP062 may require additional corrosion protection measures in certain environments, but it can be effectively protected with appropriate coatings or surface treatments.

Is HSS-SP062 suitable for cold forming processes?

- Yes, HSS-SP062 can be cold-formed to achieve complex shapes without sacrificing its mechanical properties, making it versatile for technical solutions requiring intricate designs.

Are there any specific design considerations when using HSS-SP062?

- Designers should consider the high strength and stiffness of HSS-SP062 when integrating it into technical solutions, as well as the potential for reduced material usage and cost savings.

What standards or specifications govern the use of HSS-SP062?

- HSS-SP062 is typically governed by industry standards such as ASTM A1085 or EN 10210, which outline the requirements for manufacturing and testing of high-strength steel materials.

Are there any limitations to the use of HSS-SP062 in technical solutions?

- While HSS-SP062 offers exceptional strength, it may not be suitable for applications requiring extreme ductility or impact resistance, so careful consideration of specific project requirements is essential.